Milk Can Plunger

Price 250-2000 INR/ Piece

Milk Can Plunger Specification

- Product Type

- Milk Can Plunger

- General Use

- Stirring/Agitating Milk in Cans

- Material

- Stainless Steel

- Type

- Manual Plunger

- Capacity

- Suitable for Standard Milk Cans (30-40 Ltr)

- Weight (kg)

- Approx. 0.8-1.2 kg

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Cleaning System

- Manual Clean

- Sterilization Method

- Manual Cleaning/Sterilization

- Dimension (L*W*H)

- Approx. 60-65 cm length x 12-14 cm Disc Dia

- Feature

- Corrosion Resistant, Easy to Use, Durable Build, Easy to Clean

- Color

- Silver (Polished Steel)

Milk Can Plunger Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

About Milk Can Plunger

Features:

- Rugged construction

- Less maintenance

- Easy to operate

Specifications:

- 6" diameter convex disc screwed with nuts to the 36"/30" long rod of 8 mm diameter

- 165 mm diameter convex disc of 1.2 mm thick screwed with nuts to the 855 mm long rod of 8 mm diameter

- 12" diameter convex disc screwed with nuts to the 6 long rod of 12.5 mm diameter

- 12" diameter convex disc attached to 6 Long rod with 3 supports by TIG Welding

- 6" diameter convex disc screwed with nuts to the 36"/30" long rod of 10 mm diameter

Efficient Mixing for Quality Milk

Ensuring proper milk agitation is crucial for maintaining consistency and freshness. The Milk Can Plungers perforated disc design allows thorough mixing, preventing cream separation and ensuring even temperature. This process enhances milk quality, making it suitable for dairy farms and collection centers focused on delivering the best product.

Designed for Ease and Durability

Built with an ergonomic grip and polished stainless steel, this manual plunger is both comfortable to use and highly durable. Its corrosion-resistant finish protects against daily wear in demanding environments, while the easy-to-clean surface guarantees food safety and hygiene. No assembly is required, making it instantly ready for routine dairy operations.

FAQs of Milk Can Plunger:

Q: How is the Milk Can Plunger used for mixing and agitating milk?

A: The plunger is manually inserted into the milk can and moved up and down or in a stirring motion. The perforated circular disc enables thorough mixing, ensuring even distribution of cream and temperature throughout the 3040 liter capacity milk can.Q: What makes the ergonomic grip handle beneficial during use?

A: The ergonomic grip handle provides comfort and control, making it easier to perform repetitive stirring actions without causing strain, which is especially important for long or frequent mixing sessions in dairy operations.Q: When should I use the Milk Can Plunger during the milk processing cycle?

A: Use the plunger immediately after milk collection and before processing or storage to ensure the milk remains homogenous and prevents cream separation, which is vital for maintaining product quality.Q: Where is this Milk Can Plunger most effectively utilized?

A: This plunger is ideal for use in dairy farms, milk collection centers, or any facility that processes or transports milk in standard steel cans, ensuring efficient agitation wherever needed.Q: What is the cleaning and sterilization process for this plunger?

A: The plunger should be manually cleaned and sterilized after each use using warm water and food-safe cleaning agents, ensuring all milk residues are removed and the surface remains hygienic for future use.Q: What are the key benefits of using a stainless steel, corrosion-resistant plunger?

A: Stainless steel construction guarantees durability, resistance to rust and corrosion, and makes the plunger safe for prolonged use in food processing environments. Its easy-to-clean polished surface also helps in maintaining optimal hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milk Collection Accessories Category

Milk Strainer

Price nan INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Manual

Color : Silver

Dimension (L*W*H) : Approx. 21 cm diameter x 8 cm height

Sterilization Method : Other, Boiling water/manual clean

SS Milk Sampler

Price 250-2000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Handheld Sampler

Color : Silver

Dimension (L*W*H) : Approx. 25cm x 3cm x 3cm (varies per model)

Sterilization Method : Other, Autoclavable/Sterilizable

SS Milk Sample Bottles

Price 250-2000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Milk Sample Testing Bottle

Color : Silver (Natural Stainless Steel Finish)

Dimension (L*W*H) : Varies by capacity, typically cylindrical, diameter 4060 mm, height 100160 mm

Sterilization Method : Other, Steam or Boiling

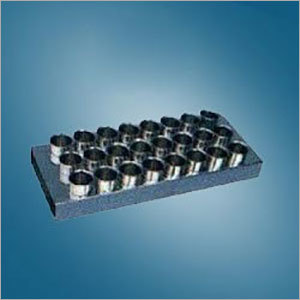

SS Milk Sample Bottle Tray

Price 250-2000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Milk Sample Bottle Tray

Color : Silver

Dimension (L*W*H) : Approx. 36 cm x 21 cm x 6 cm

Sterilization Method : Other, Can be autoclaved

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS